Become Salsa Jeans

The Portuguese brand Salsa Jeans, which specializes in jeanswear, is part of the IVN Group, S.A., which has been established in Vila Nova de Famalicão since 1994.

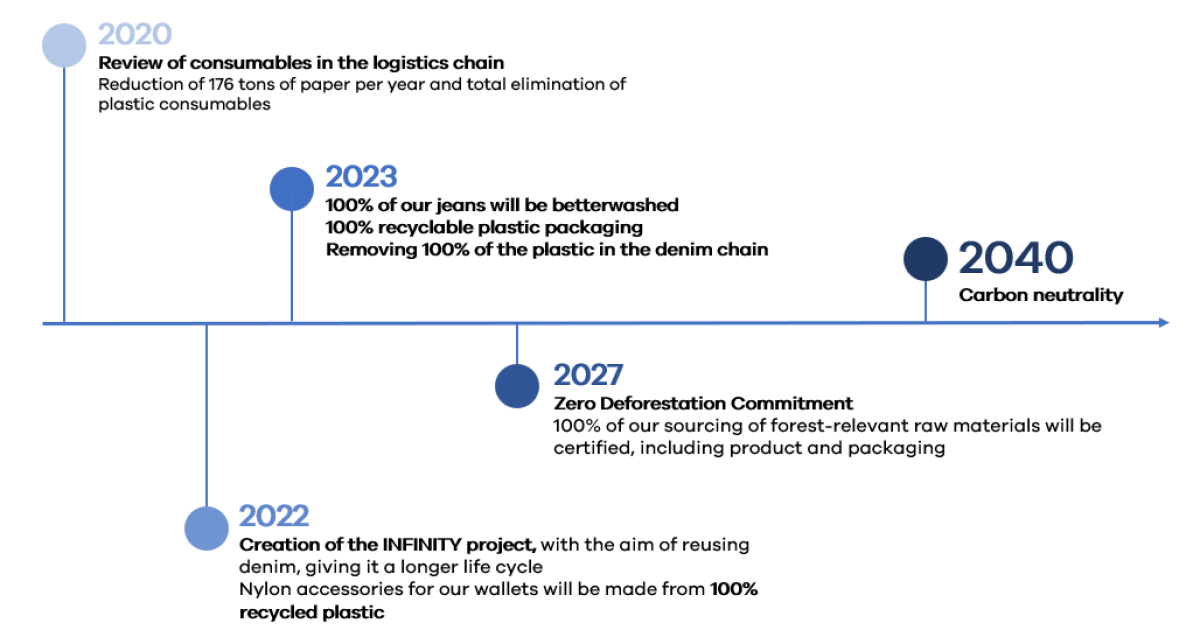

For this Group, topics such as environmental and social responsibility, respect for the ecosystem, sustainability and recycling are of paramount importance and a key focus. As a result of this thinking, the Become Salsa Jeans concept emerged: "Become is our way of being and our commitment to people and the planet. It's our environmental and social responsibility to do what we do best while respecting the ecosystem in which we operate. It's about being conscious in the production and distribution of our products, fair and kind to the people who are part of the process and giving back to the community, creating examples that pave the way for future generations."

The brand's main objectives:

HOW CAN I BECOME PART OF THE PROGRAM?

- Program Infinity / Give your jeans an infinite life: We'll fix ripped jeans, add patches, increase a size, make them shorter, tighter... the possibilities are endless, you choose!" (All you have to do is hand in the garment at one of our locations, for more information please link). If the item is no longer repairable or the customer no longer wants it repaired, they can always leave the item on site for that purpose, and they will receive rewards for the action (link).

- Betterwash: jeans washing process which, by combining the best existing technologies and the decades of experience of the production teams, makes it possible to use an average of 58% less water, a process certified by the Control Union. (For more information see link):

- Laser: Efficient and sustainable, laser technology does not consume any water and provides the perfect finish without altering the authentic look of the jeans;

- Ozone washing: Washing that uses electricity and oxygen to replace many of the chemicals normally used in a traditional washing process. This is a water-free technique;

- E-flow: The e-Flow technology uses spray application of the product, allowing a significant reduction in chemical, water, and energy consumption.